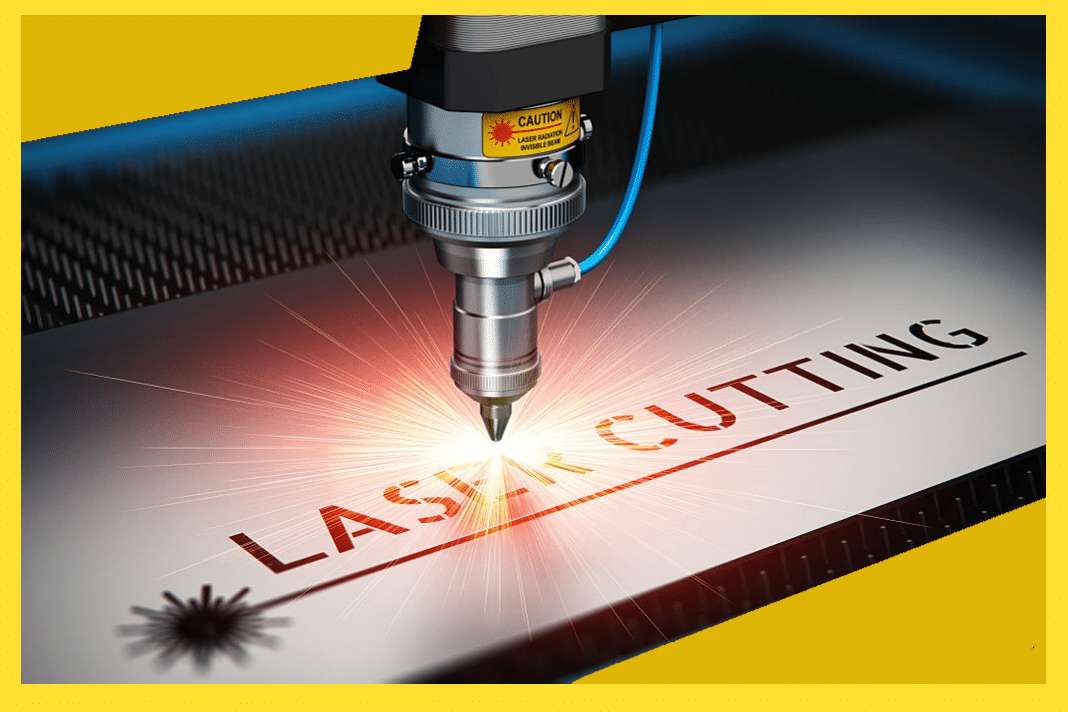

What exactly is laser engraving, and how does it function?

It’s a method of burning materials with high-intensity lasers, producing fumes that are used to engrave lasting, deep impressions. The laser beam acts like a chisel, removing layers from the material’s surface and incising lines in it. To generate the intense heat required for vaporisation, a laser is used to target localised regions with huge quantities of energy.

In this article, you’ll learn everything there is to know about laser engraving, thanks to The Engraving People helping us break it down.

Should You Choose Laser Engraving or Laser Etching?

When it comes to determining which laser marking technique is best for your job, there are three major things to consider:

- The resistance of the marking to fade: its ability to be legible in extreme situations

- The laser marking speed: time to mark that prevents workplace bottlenecks

- The material being marked: the suitability of the marking technique to it

Metal etching with laser technology is commonly used on metal components that will be subjected to a variety of usage conditions or surface treatments. Steel and aluminium may be engraved (anodised and die-casting aluminium).

The most significant feature of this method is that it can print 2D symbols with enhanced readability after post-process treatments. These solutions include shot blasting, e-coating, and heat treatments, all of which are used to tackle the most difficult traceability problems. However, if engraving the most durable identifiers isn’t required, laser etching is often utilised since it is a high-speed technique that doesn’t necessitate as much ablation.

Laser etching can be used to etch a wider range of materials, including steel, aluminium, anodized aluminium, lead, magnesium, and zinc. Metals such as stainless steel are also marked with a laser method known as laser annealing.

Solid to Gas: How It Works in a Nutshell

When the material surface is engraved with a laser, it melts, as in laser etching. In contrast to this process, laser engraving sublimes the material surface by evaporating it. When a substance’s temperature rises, its molecules absorb thermal energy. The molecules then shed this heat when the substance reaches 300°F (150°C). However, because the material does not transition from solid to liquid and back to gas by absorbing sufficient thermal energy, it never becomes a liquid.

To sublimate, the laser engraving machine must deliver enough heat to the surface of the substance in milliseconds in order for it to reach its vaporization temperature. When it comes to sublimation, laser engravers are rather strong instruments.

When the temperature reaches this point, materials are evaporated into vapours. As a result, when you buy a laser system, it should always include a fume extraction system and an air knife to safeguard the workplace and the laser’s lens.

For this, fiber lasers are the ideal engraving tools because they produce a wavelength that is effective with metals.

How Do You Engrave High-Contrast, High-Quality Marks?

You can see the chaotic surface that results from laser engraving if you look at enlarged photos. The light is trapped in deep grooves (the engraving depth may reach up to 0.5 mm), making permanent marks darker than they would be without the laser engraving process.

When you laser engraves a surface, you have two options for generating contrast.

- The first (and quicker) method, on the other hand, creates a contrast between the base material and the black marks etched. This technique is only advised if the bare material colour is light enough to create high contrast.

- The second (and much longer) method is more precise because it etches black and white marks with a laser. The laser system uses both laser engraving (to create the black markings) and laser etching (to produce the white markings).

Leave a Reply